WHAT YOU NEED TO GET STARTED

To get started, you’ll need a Heat Press, some Heat Transfers, and blank shirts. Decorating with a heat press is an easy, cost-effective way to enter the T-shirt printing business. It allows for personalisation at scale on a wide variety of items and fabrics. Because of the ease of use and versatility, this is the go-to among start-up businesses and entrepreneurs.

With a professional setup costing starting at £600. It’s the most affordable professional decorating setup available on the market.

WHAT ARE HEAT TRANSFERS

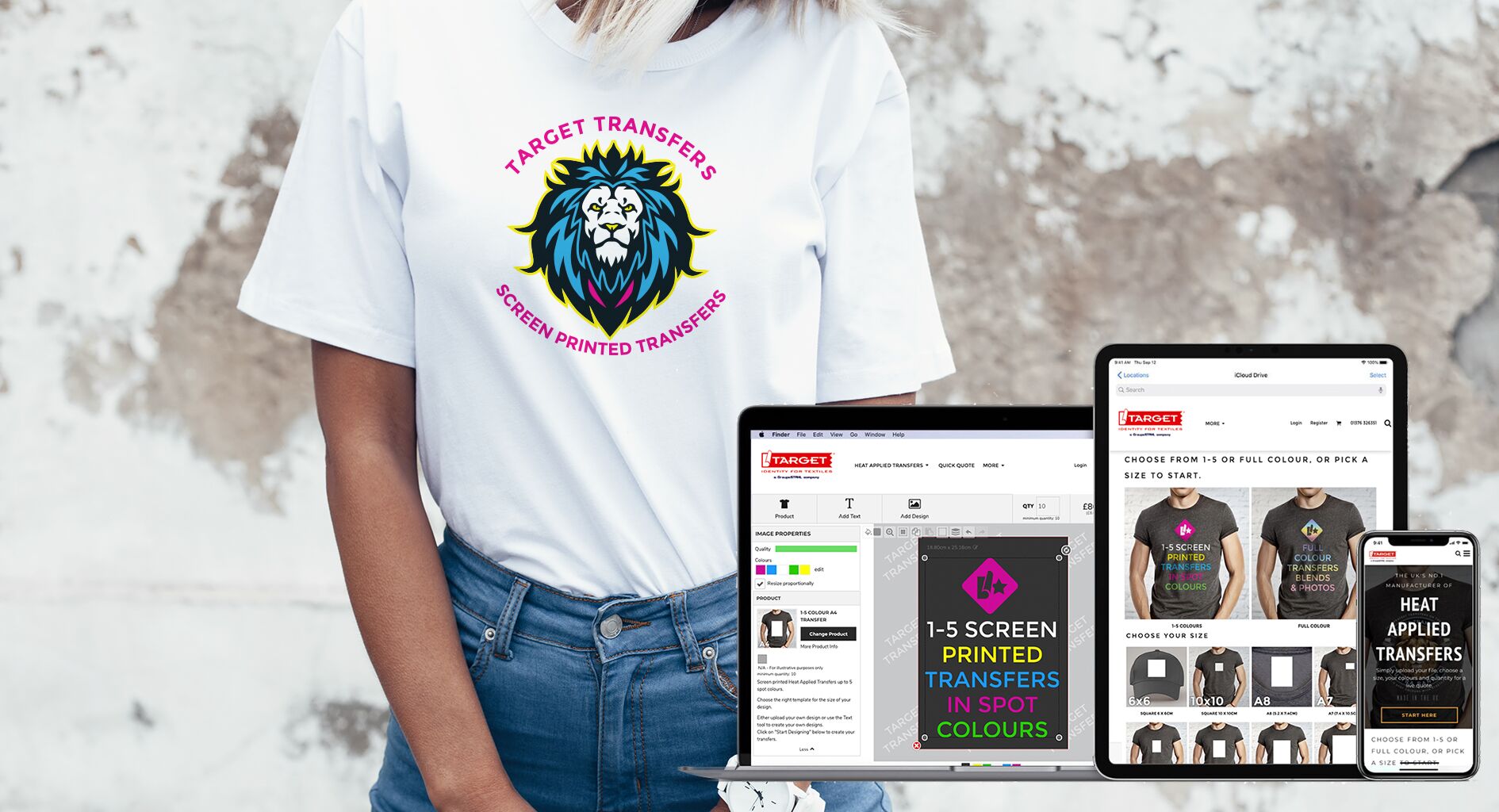

With Custom Heat Transfers, all you need to do is provide artwork. Once you are happy with your design, add it to the uploader and we will bring it to life. Then in your own time press on demand by fusing it under a Heat Press for 10-12 seconds.

With Custom Transfers, there are two types of transfers to look for: Screen Printed and UltraColour. Both of these will last the lifetime of the t-shirt.

WHEN WOULD YOU USE HEAT TRANSFERS

Heat Transfers can be applied to any textile/ fabric that can take heat. Heat transfers are used to get a soft finish, that feels like part of the garment. And to get vibrant colours, neons and metallic finishes from your designs.

Common uses for heat transfers include: Full size graphic prints, chest prints, sports names/ numbers, leavers designs. hoodie sleeves, neck labels, cap/ hat prints, neck labels, bags and much more.

HEAT TRANSFER TYPES EXPLAINED

SCREEN PRINTED TRANSFERS (1-5 SPOT COLOURS)

Created with ink, screen printed transfers are printed onto release paper and applied with a heat press. They are great for large jobs over 50 pieces and graphics with 5 or less colours. Screen printed benefits inlcude:

ULTRACOLOUR (FULL COLOUR TRANSFERS)

Are a combination of the best qualities of screen and digital. Get the soft, detailed finish of screen with the unlimited colour and gradients of digital. This eco-friendly transfer is fast becoming one of the most sought-after transfer choices. UltraColour Benefits inlcude:

PRICING STRATEGY

There are lots of variables that go into pricing your merchandise: your costs, overhead expenses, and what your competition is charging, to name just a few. Pricing strategies can be complex but the basic rules are straightforward. Your price must cover costs and give you profits. Review your prices often to make sure they’re still in line with your costs, demand, competition, and profit objectives.

When making an investment for your T-shirt business, calculate the payoff to better understand your ROI. For example, if a press costs £1,350* and comes with a 5-year warranty, your annual cost to own the heat press is £270 per year. *Based on 40x50cm Hotronix Auto Open Heat Press.

THE PAYOFF

To figure out how many sales you will need to pay off the cost of your heat press, take the total cost of heat printing tools and divide it by the profit per item. Follow this example to break it down further:

|

Investment Cost |

Average Order Profit |

|

Price of Heat Press: £1,350 |

Average Selling Price: £20 |

|

Price of Accessories: £170 |

Average Cost Per Item: £6 |

|

Total Cost: £1,520 |

Profit Per Item: £14 |

Number of items sold to payoff (Total Cost ÷ Profit): 108 items or 2 per week.

For 108 shirts the average price for a one colour transfer starts at £0.55, and a blank t-shirt would be £1.00.

If you think you can sell 108 t-shirts, then you are ready to start.